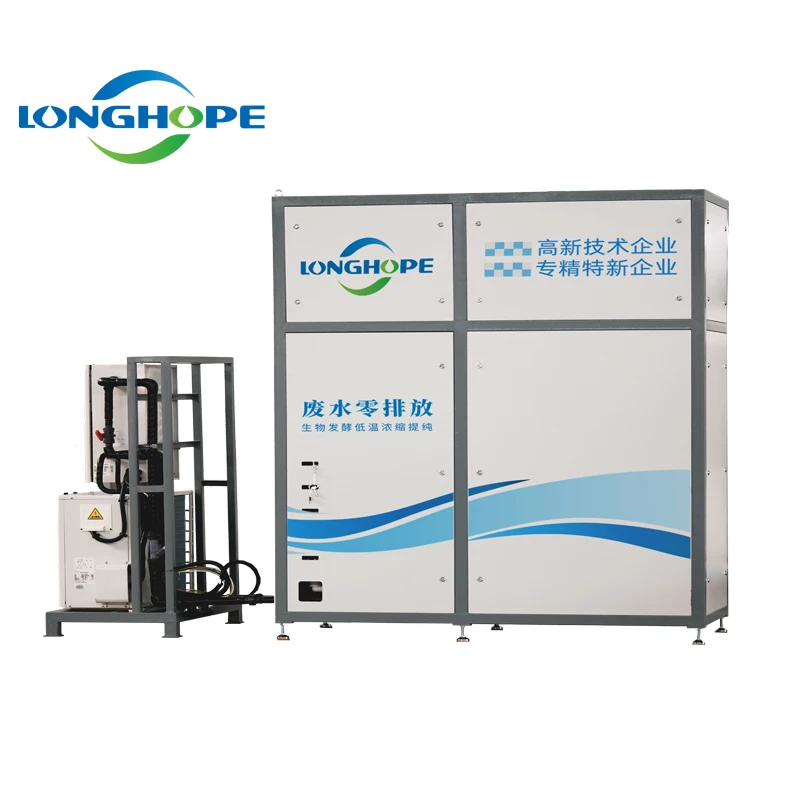

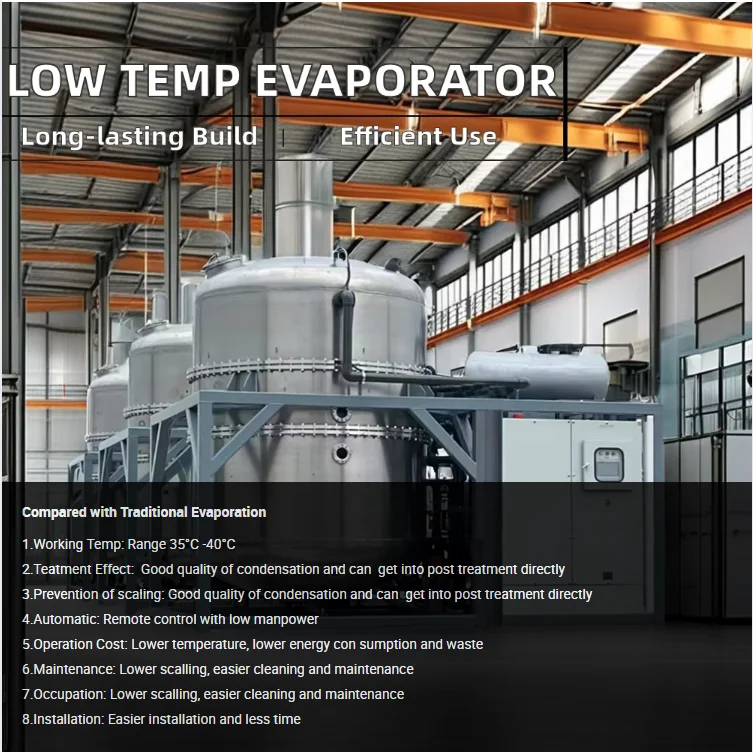

The boiling chamber is negative pressure at-95 to-97kPa under vacuum condition, raw material is automatically sucked into chamber under negative pressure. Meanwhile, the heat pump system will makes heat exchange device into evaporation and condensation two parts. Circulation system sprays raw wastewater onto the evaporation part nebulized, water become steam after evaporation and rise to condensing become condensate. The condensate flows to condensation vessel and the concentration remains in boiling chamber, both of them will discharge automatically when reach pre-setted rate.

Conveniently Installed Low Temperature Electric Heat Pump Vacuum Evaporator for Machining Industry

The machine has an automatic scraper system, which minimizes fouling and enables uninterrupted operation. To achieve a fully automated process with minimum direct supervision, installation is convenient due to the modular design.

Description

Product Description

Evaporator Series

Products":[1601400069786,62557078164,1601395042695,62002114202]}}},"version":1}' class="icbu-pc-detailSellerRecommend magic-6">

Type specification

Model(L/d) |

evaporative power(L/h) |

installed power(kw) |

Consumption(w/l) |

outline dimension(L×B×H) |

V-HP SF- 1000

|

45 |

9.83 |

100-120 |

3.0×0.9×2.8 |

V-HP SF- 2500

|

110 |

18.13 |

80-100 |

3.8×1.2×3.0 |

V-HP SF- 5000

|

216 |

34.50 |

80-100 |

4.0×1.6×3.2 |

V-HP SF- 8000

|

336 |

48.00 |

80-100 |

4.3×1.8×3.4 |

V-HP SF- 10000

|

440 |

64.35 |

60-100 |

4.5×2.0×3.6 |

V-HP SF- 20000

|

870 |

125.00 |

60-100 |

6.0×3.2×3.8 |

V-HP SF-35000 |

1450 |

195.00 |

60-100 |

7.0×3.2×4.0 |

Our Advantages

Technical Characteriatics

1.Intelligent:fully automatic operation,remote monitoring of moblie device terminals.2.Ensures that the equipment can still operate normally in high temperature enviroments.3.Liqyid handing: Atomized liquids to achieve maximum evaporation efficiency.4.Vacuum system:independent water ring vacuum system,with automatic start and stop function.5.Avoid fouling inside the equipment and increase the service life of the equipment.6.To ensure that the liquid will not freeze inside the equipment,protect the equipment and pipe.7.Continuous evaporation mode ,no system venting and shutdown,more energy-saving and efficient.8.Supporting facilities:only industrial pwer supply , equipment valves are electric valves.

Typical Application

Elecdtroplating Wastewater

Inlet: COD 5,890mg/L, NH3-N 198mg/L, Conductivity 29,750us/cm.

Outlet: COD 108mg/L, NH3-N 14mg/L, Conductivity 68us/cm.Vacuum Evaporation Rate 3%.

Oil Emulsion Wastewater

Inlet: COD 25,500mg/L, NH3-N 1,335mg/L, Conductivity 93,000us/cm.

Outlet: COD 325mg/L, NH3-N 65mg/L, Conductivity 380us/cm.

Vacuum Evaporation Rate 3%.

Landfill Leachate

Inlet: COD 122,750mg/L, NH3-N 625mg/L, Conductivity 280,000us/cm.

Outlet: COD 350mg/L, NH3-N 6mg/L, Conductivity 85us/cm.Vacuum Evaporation Rate10%.

Customer Photos

Certifications

Company Profile

Company Profile

LongHope Environmental is located in Wuxi, which is 50mins car driving from Shanghai. We are committed to R&D and manufacturing heat pump low-temperature evaporation equipment. Our focus is on the high concentration&high salt wastewater evaporation, the hazardous liquid reduction and the precious metal recycling. Besides, we can provide a turnkey and customized solution for clients. We have a strong R&D team with large projects management experience. What's more, we had cooperated with many famous Chinese universities to establish labora tory, in which the Low-Temp heat pump evaporators and crystallizers have been successful developed.

Packing & Delivery

FAQ