1, low temperature heat pump evaporator under the vacuum negative pressure to reduce the boiling point to a certain extent, so

that the original liquid after heating in more than 30 degrees and then boiling evaporation, evaporation of steam through the

condensation system condensed into liquid water through the drainage tank discharge, and then according to the specific gravity of

the water concentration reduction water rate can reach 95%.

Highly Efficient and Energy Saving Low Temperature Heat Pump Vacuum Crystallizer Made in China

That hand-operated machine was a heater to 35–40 °C under vacuum, using electricity as the only heat source. It comes equipped with a built-in scraper to enhance drying efficiency and separate crystals, making it highly suitable for high-salt wastewater and concentrated waste fluids.

Description

Product Description

High-Efficient ZLD Solution for Water Treatment Low Temperature Vacuum Evaporation and Crystallization Machinery

Crystallizer Series

The crystallization chamber is negative pressure at -95 to -97kPa under vacuum condition, raw material is automatically sucked into chamber under negative pressure. Meanwhile, the heat pump system will makes heat exchange device into evaporation and condensation two parts, the chamber is equipped with a scrapper and jacketed layer, continuous stirring of material and the jacketed surface going on evaporation. The water evaporates into steam and flows upto condensation chamber and becomes distilled water. Distilled water flows to condensation vessel and discharges automatically. Solid materil will be disacharged automatically by scarpper at last.

Specification

Modle(L/d) |

evaporative power(L/h) |

installed power(kw) |

Consumption(w/l) |

outline dimension(L×B×H) |

V-CT-SF- 500

|

22 |

8 |

250-270 |

2.7×1.7×2.3

|

V-CT-SF-1000 |

45 |

12 |

195-215 |

2.7×1.8×2.8 |

V-CT-SF-2000 |

90 |

120 |

195-215 |

4.4×1.9×3.3 |

V-CT-SF-3000 |

125 |

30 |

190-210 |

4.4×2.1×3.8 |

V-CT-SF-5000 |

216 |

55 |

190-210 |

4.4×4.2×3.8 |

V-CT-SF-10000 |

440 |

110 |

190-210 |

10.0×4.4×3.8 |

Product Details

2, the heat pump evaporator uses steam recompression or refrigeration heat pump technology to achieve thermal cycle and balance,

this energy-saving technology compared with electric heating, can introduce 80% of the electrical energy, which is based on the

principles of physics, the same amount of material from the liquid into the gas process, the need for quantitative absorption of

heat energy.

this energy-saving technology compared with electric heating, can introduce 80% of the electrical energy, which is based on the

principles of physics, the same amount of material from the liquid into the gas process, the need for quantitative absorption of

heat energy.

3, the material can be changed from gaseous to liquid, and can release the same amount of heat energy. Using this principle, when

the device is used to treat waste water, the heat energy required for evaporating waste water is released after steam condensation

and condensate cooling.

Lower temperature, lower energy consumption and waste. Lower scalling, easier cleaning and maintenance. Integrated design, lower

occupation, Plug&Play. Easier installation and less time.

the device is used to treat waste water, the heat energy required for evaporating waste water is released after steam condensation

and condensate cooling.

Lower temperature, lower energy consumption and waste. Lower scalling, easier cleaning and maintenance. Integrated design, lower

occupation, Plug&Play. Easier installation and less time.

Forced circulation evaporation crystallizer adopts forced circulation process for evaporating crystallization of materials. When

evaporating crystallization, the forced circulation pump is used for evaporating crystallization, and the heated or cooled

materials re-enter the crystallization chamber, so the cycle is continuous, which belongs to the slurry circulation type. It can

evaporating crystallization, the forced circulation pump is used for evaporating crystallization, and the heated or cooled

materials re-enter the crystallization chamber, so the cycle is continuous, which belongs to the slurry circulation type. It can

be operated continuously or intermittently.

The forced circulation of the evaporative crystallizer, whose internal structure enables the effective and rapid separation of the

crystal and the clear liquid. The whole process is evaporation under vacuum conditions, the temperature is relatively low, the

evaporation speed is fast, the evaporation energy consumption is low, and the evaporation concentration is high.

crystal and the clear liquid. The whole process is evaporation under vacuum conditions, the temperature is relatively low, the

evaporation speed is fast, the evaporation energy consumption is low, and the evaporation concentration is high.

Company Profile

Longhope Environmental is listed as the high-tech enterprise, Jiangsu technological enterprise, member of Jiangsu Association of Science & Technology Innovations. We achieved ISO9001 and ce certification, and AAA credit certification. Low-temp heat pump evaporators&crystallizers through independent research and development passed the new technology and new product identification of the industry and information technology department, Jiangsu province,obtained the product performance testing certification by Wuxi inspection and testing institute and passed Wuxi high-tech product identificationobtained the laboratory test report (COP≥9.5) of Trane Air Conditioning System (China) Co., Ltd. Low-temp evaporation and crys·tallization received more than 40 national inventions, utility patents, and soft certificates. We have provided technical support and services for thousands of customers, and Products are gradually moving to the international market while being sold in the domestic market.

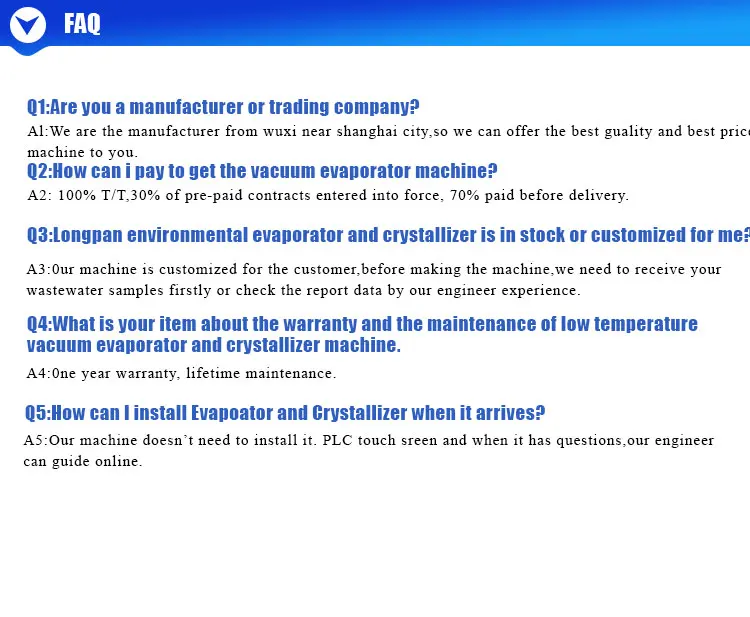

FAQ