industrial water treatment plant

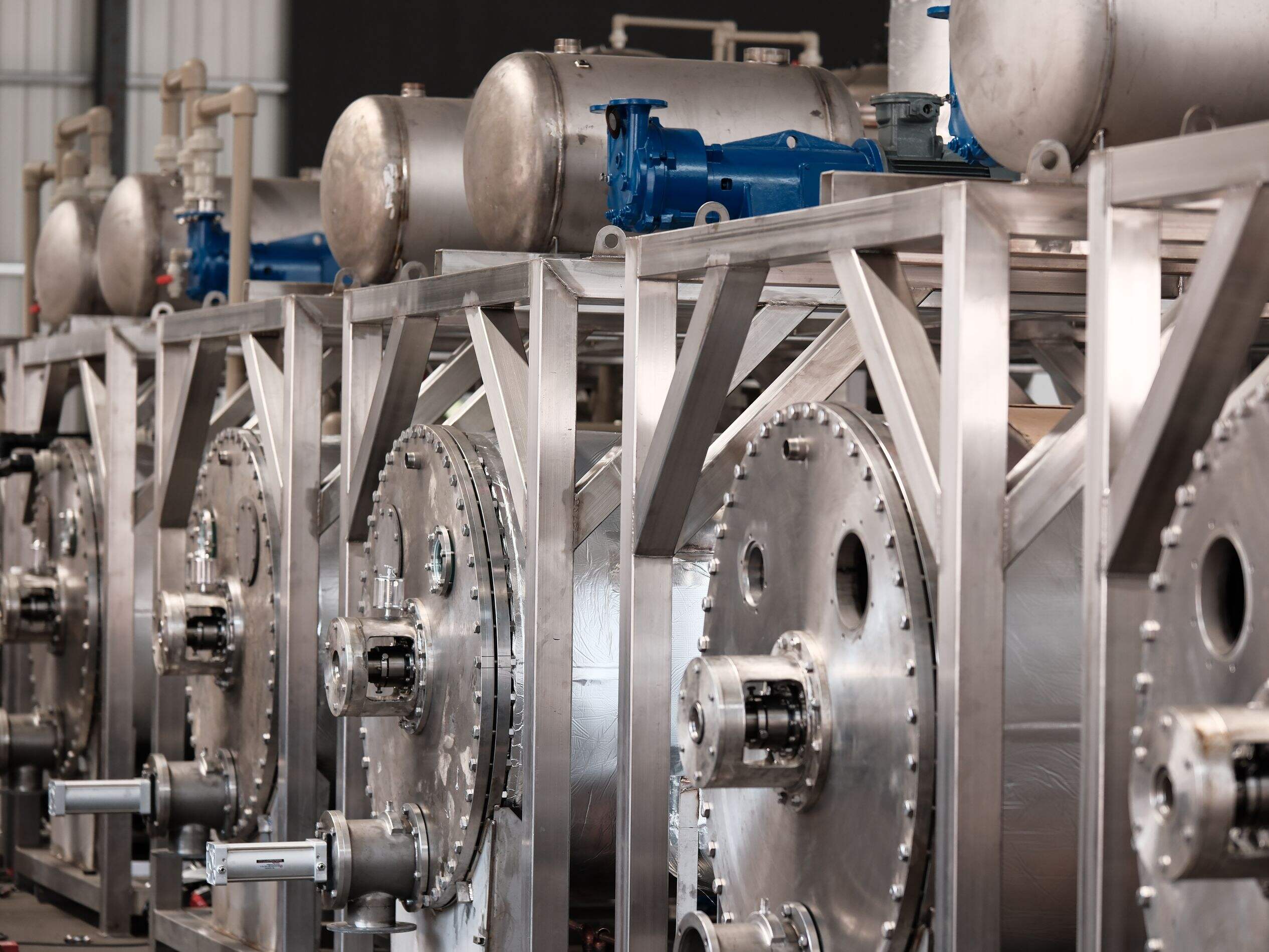

An industrial water treatment plant represents a sophisticated system designed to purify and process water for various industrial applications. These facilities employ advanced technologies to remove contaminants, adjust chemical composition, and ensure water quality meets specific industrial requirements. The plant typically incorporates multiple treatment stages, including preliminary screening, primary clarification, biological treatment, and advanced filtration processes. Key components include settling tanks, biological reactors, membrane filtration systems, and chemical dosing equipment. The facility can handle large volumes of water, processing thousands of gallons per hour while maintaining consistent quality standards. Modern plants feature automated control systems, real-time monitoring capabilities, and energy-efficient operations. They are essential in industries such as manufacturing, power generation, chemical processing, and food and beverage production. The treatment process can be customized to address specific water quality challenges, whether it's removing heavy metals, reducing organic compounds, or achieving ultra-pure water standards. These plants also incorporate sustainable practices, often including water recycling systems and waste minimization protocols. With advanced instrumentation and quality control measures, they ensure compliance with environmental regulations while optimizing operational efficiency.