vacuum distillation method

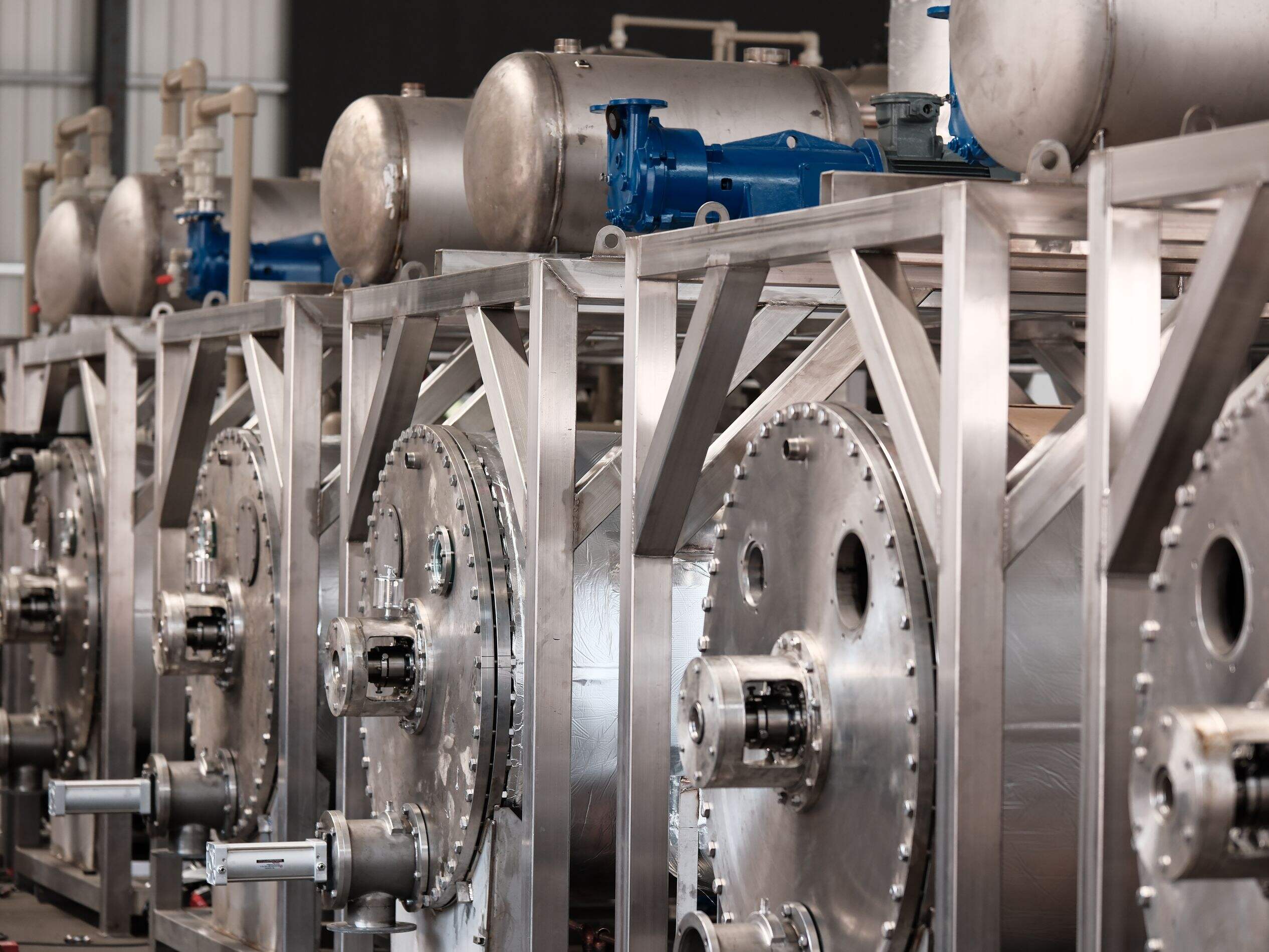

Vacuum distillation is an advanced separation technique that operates under reduced pressure conditions, enabling the separation of compounds at temperatures lower than their normal boiling points. This sophisticated process involves creating a vacuum environment within the distillation system, which effectively lowers the boiling points of the substances being separated. The method proves particularly valuable when dealing with heat-sensitive materials or compounds with high boiling points that might decompose at atmospheric pressure. The technology employs specialized equipment, including vacuum pumps, condensers, and precise temperature control systems, working in harmony to maintain optimal separation conditions. The process begins by reducing the system pressure, followed by careful heating of the mixture to achieve selective vaporization of components. As the vapors rise, they encounter cooling surfaces where they condense and are collected separately. This method finds extensive applications across various industries, including pharmaceutical manufacturing, petrochemical processing, and fine chemical production. It's especially crucial in situations where traditional atmospheric distillation might lead to product degradation or when highly efficient separation is required for high-value compounds. The precise control over operating conditions allows for exceptional purity levels in the final products, making it an indispensable technique in modern industrial processes.