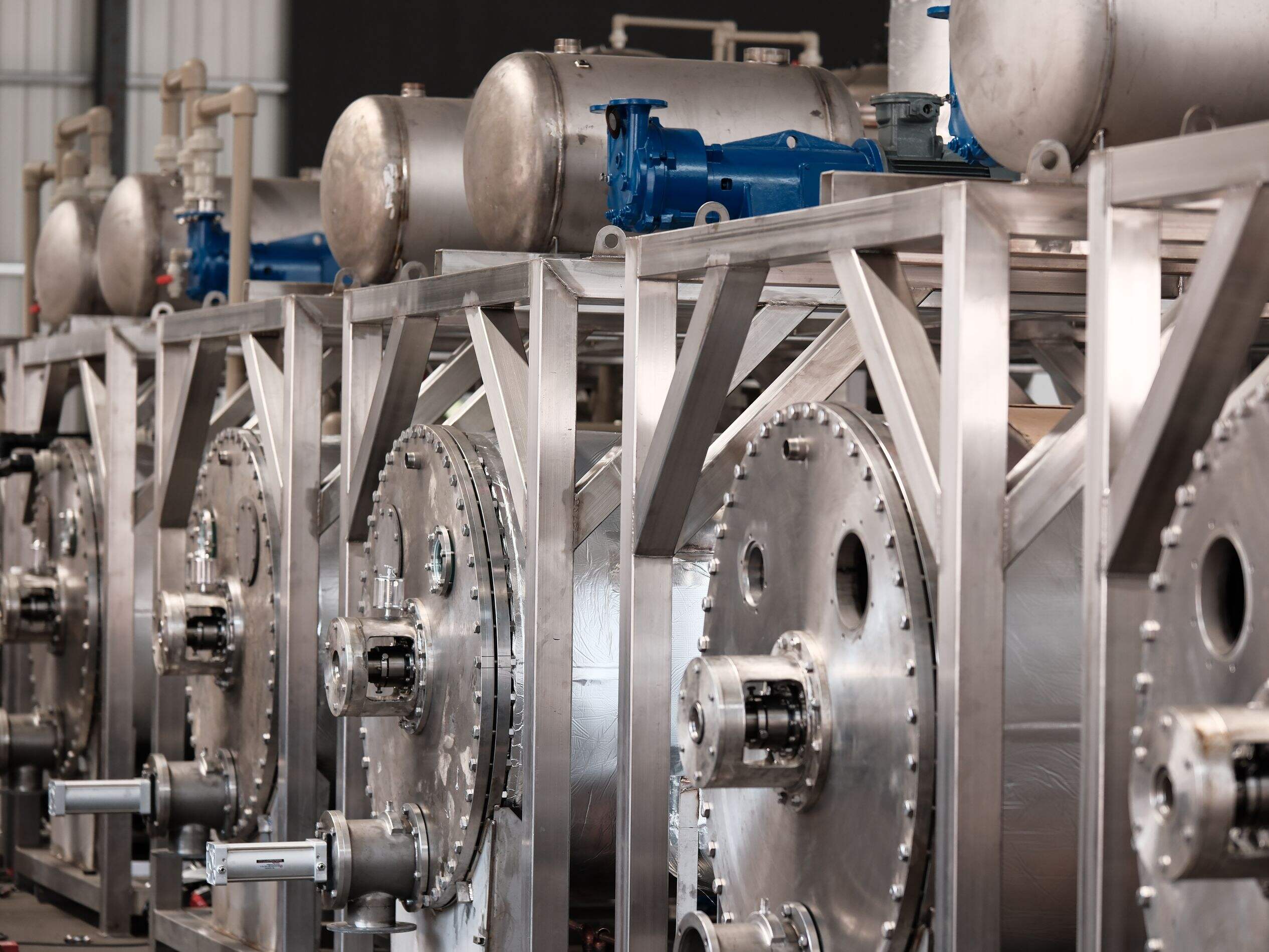

vacuum evaporation machine

A vacuum evaporation machine represents a sophisticated industrial solution designed for efficient liquid concentration and separation processes. This advanced equipment operates by creating a controlled vacuum environment that significantly reduces the boiling point of liquids, enabling evaporation at lower temperatures. The machine consists of several key components, including a vacuum chamber, heating system, condensation unit, and control panel for precise operation management. The technology employs the principle of reduced pressure to facilitate the separation of volatile compounds from solutions, making it particularly valuable in various industrial applications. These machines can handle multiple types of solutions, from chemical compounds to food products, with exceptional precision and efficiency. The system's design incorporates advanced heat exchange mechanisms that optimize energy utilization while maintaining product quality. Modern vacuum evaporation machines feature automated control systems that monitor and adjust operating parameters in real-time, ensuring consistent results and minimal operator intervention. The technology's versatility allows for processing both heat-sensitive materials and robust solutions, making it indispensable in pharmaceutical, chemical, food processing, and waste treatment industries. With customizable configurations and capacity options, these machines can be tailored to meet specific production requirements while maintaining high standards of operation efficiency.